In the oil and gas industry, achieving precise pressure measurements is more than a technical necessity—it’s a safety imperative. One critical component that plays a vital role in this realm is the hammer union pressure sensor. These sensors are designed to withstand the rigors of harsh environments while delivering reliable data. But even with advancements in technology, have you wondered why failures still occur during pressure measurement setups? Understanding these failures can lead to better solutions and improved operational efficacy.

Traditional Solution Flaws

Traditional pressure measurement techniques often rely on outdated methodologies that can cause significant inaccuracies—particularly in high-pressure environments. They may experience issues like lagging responses or deviations due to temperature fluctuations or external interferences. Moreover, older sensors often lack the robustness needed for demanding field operations, which can lead to erroneous readings and, ultimately, costly downtimes. This is unacceptable in industries where every second counts. As the demand rises for more efficient and accurate pressure measurements, it’s clear that these traditional solutions can fall short.

New Technology Principles

Enter the realm of modern hammer union pressure sensors which leverage cutting-edge technologies—from enhanced diagnostic capabilities to digital interfaces. These sensors employ advanced operational principles, such as real-time data processing and enhanced signal conditioning, which ensure high accuracy and reliability. By integrating features like edge computing nodes and superior biocompatibility materials, these new devices not only withstand extreme pressure scenarios but also provide real-time data analytics. This benefits not just operational efficiency but also safety protocols essential for maintaining standards in high-pressure applications.

Quantified User Benefits

The implementation of hammer union pressure sensors has proven to be a game-changer. Users report significantly reduced downtime—often by as much as 30%—due to real-time responsiveness and predictive maintenance capabilities. These advanced sensors enable operators to make data-driven decisions faster, leading to operational savings often exceeding 15% over time. The quantifiable benefits are profound, illustrating that investments in high-quality sensors convert to immediate and long-term advantages in performance and safety.

Conclusion: Actionable Evaluation Criteria

When evaluating pressure measurement solutions, one must ensure they verify these three critical metrics: ① Accuracy and Reliability ② Compatibility with Existing Systems ③ Cost-effectiveness. By assessing these factors, organizations can make informed choices that align with operational needs, security measures, and financial stability. The right technology can lead to improved outcomes and greater peace of mind—qualities every operator seeks.

Pressure Sensor 4-20mA

When it comes to pressure measuring solutions, the pressure sensor 4 20ma is notable for its versatility and reliability. This type of sensor stands out due to its 4-20mA output signal, which provides a linear response over a wide pressure range, making it ideal for various applications. They offer higher accuracy, ensuring operators receive real-time, actionable data for critical decision-making. Due to their robust construction and ease of integration into existing systems, these sensors are favored by many in the industry. This is further enhanced by their cost-effectiveness, as they minimize maintenance needs over time. So, if you’re looking for a reliable pressure measurement device, the pressure sensor 4-20mA is worth considering.

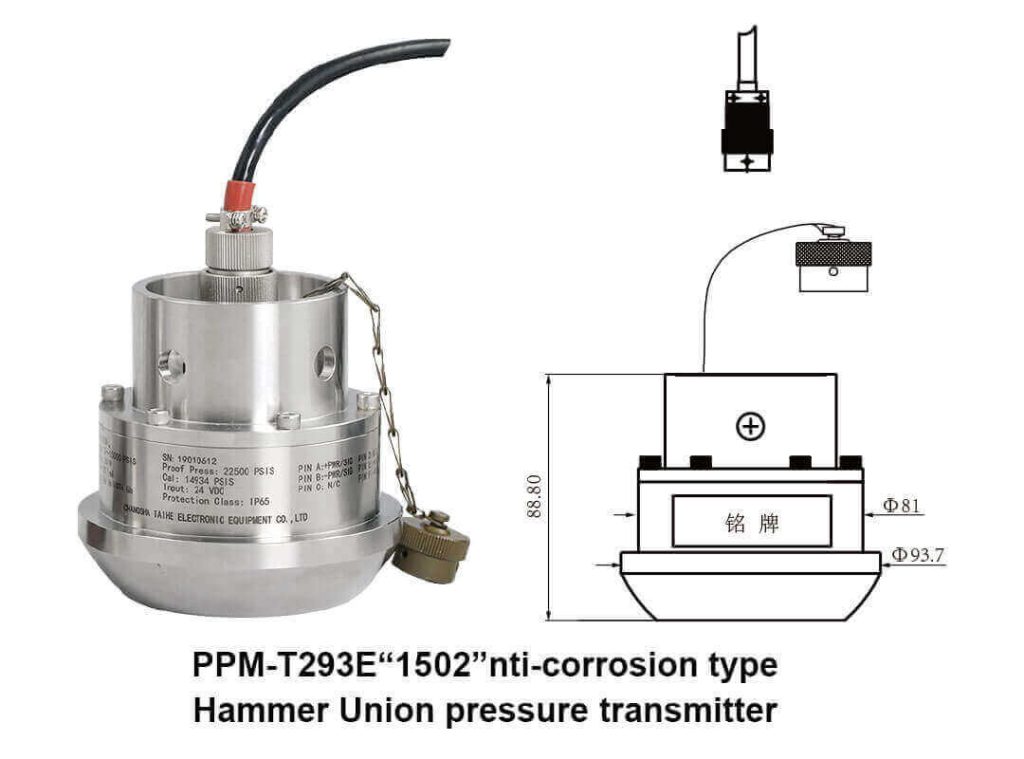

Hammer Union Pressure Transducer

The hammer union pressure transducer is another essential tool that features significant advancements over traditional pressure sensors. Designed for high-performance applications, these transducers offer superior accuracy under fluctuating environmental conditions, ensuring reliable data collection. The rugged design caters specifically to the demands of oil and gas operations; therefore, users can trust that this equipment will perform well even in the harshest environments. With features including self-diagnostics and advanced material selection, hammer union pressure transducers reduce downtime and improve overall operational efficiency. Ultimately, your choice of transducer will heavily influence your process control and safety metrics.

In summary, investing in advanced pressure sensors, such as hammer union pressure sensors and their variations like the hammer union pressure transducer and pressure sensor 4 20ma, can yield substantial benefits in terms of accuracy, reliability, and operational efficiency. For those seeking a manufacturer who offers both quality products and supply advantages, look towards CSSPM Sensor to meet your pressure measurement needs. With their comprehensive range of solutions, they can help businesses significantly enhance performance metrics and safety protocols in their operations.